Shipper | Research and reports

Operational excellence when you're tasked with saving a million dollars

Supply chain design impacts the majority of operating costs and understanding how the components of your supply chain work together is imperative.

The design of a supply chain impacts up to 80% of supply chain operating costs. By reducing complexity, it is typical to achieve 10% - 15% reduction in supply chain operating costs. If you feel the negative impacts of operational complexity, analytical techniques like network optimization can be used to model and identify opportunities to simplify your network. Understanding how the location of plants and distribution centers, supplier selection, customer service level decisions and customer assignments all work together is imperative.

"Re-evaluating your network is a prime opportunity to eliminate as much as 65% of total transportation spend and push you in best-in-class performance."

Transform your supply chain with expert network optimization

Network optimization can help an organization transform its supply chain into a powerful strategic asset by eliminating inefficiencies and reconfiguring logistics operations to align with long-term objectives. Aside from providing decision support for the number, size and location of facilities to operate, network optimization studies also aid in improving policies for sourcing, production, inventory and distribution.

Gartner recommends that network studies consider transportation as well since, “when supply chain network design and transportation modeling happen in isolation, supply chain leaders miss an opportunity to realize the true scope of benefits integration can bring.”*

Companies small or large, young or mature, and growing or stable can all benefit. Below are a few examples of situations where a network optimization study can provide value:

- Significant alteration to the supply chain network caused by acquisition, natural disaster, etc.

- Shift in customer demand or ordering patterns

- Evaluation of new business strategy or requirements

- Insufficient cost savings or service improvements from operational and tactical changes alone

- No previous supply chain evaluation in the past 3-4 years

To get started, data gathering and validation is a crucial first step. The cleaner and more complete the dataset is, the better the insights that can be derived from the study. Necessary information may include customer demand patterns, shipment histories, cost details (transportation, warehousing, etc.) and locations of all facilities and customer sites. If an organization already has its own transportation management system or other centralized data repository, this data collection exercise may be straightforward and require just one or two knowledgeable individuals to retrieve the requested data. Otherwise, more time, effort and contributors may be involved.

*Raman, K. & De Muynck, B. Integrate Network Optimization With Transportation Modeling to Enhance Your Distribution Strategy. Gartner, Inc. G00337338. Feb. 12, 2018.

Analyzing existing supply chain data

After data collection is complete, work can begin on analyzing the data and formulating a mathematical model that represents the existing supply chain network. The model should incorporate current business rules and other constraints, along with the data gathered to create an accurate reflection of existing operations. Multiple iterations may be required to ensure that all business rules are captured and that they align with the data collected.

Once the business rules and underlying data have been validated, the as-is network can be modeled to establish a baseline for comparison against alternate scenarios. A typical baseline considers at least a full year’s worth of data to account for seasonality and trends, although in some cases less data may be sufficient, especially if demand and operations are consistent throughout the year.

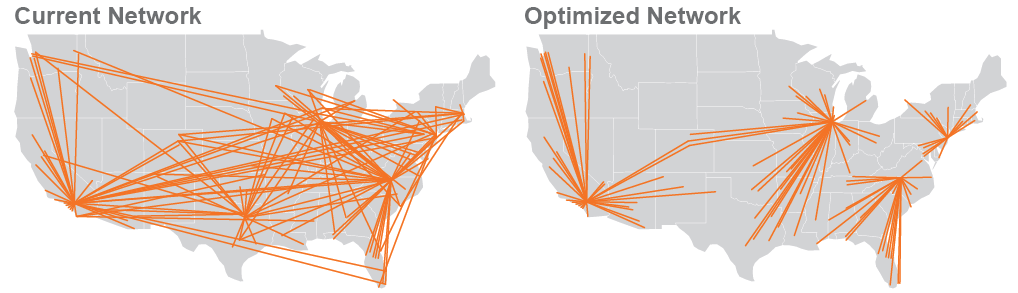

The next step is the actual optimization. Most often, this begins with optimizing the existing network under current business rules to identify any operational gains that can be achieved without significant additional investment. From there, additional scenarios may be considered that evaluate the impact of future changes. These may include implementing a new strategy, updating business rules or modifying the core network by adding, closing or relocating sites (for example, see Figure 1 below).

Example of current-state outbound network (left) and optimized network (right). In this instance, the number of facilities was reduced and transportation costs were minimized by reassigning customers to facilities based on proximity.

In addition, scenarios that incorporate alternate assumptions or input data can be utilized to evaluate and optimize the robustness of the network. However, when considering these what-if scenarios, it is important to have reliable cost benchmarking data for validation purposes. Inaccurate assumptions about cost in an envisioned future-state scenario can render the resulting optimization invalid.

Supply chain assessment: A clear path to substantial savings

Schneider Logistics has been helping its customers optimize supply chain networks for decades. Its broad portfolio of services includes consulting and professional services to assist customers with network optimization, as well as other types of supply chain and transportation studies. Organizations that are looking to unlock the potential of their supply chain, without investing the resources required for a full-fledged engineering study, can reach out to Schneider to request a supply chain assessment.

An assessment is a low-cost, low-commitment way to identify cost savings opportunities and a timeline for realizing savings within a supply chain network, obtain reliable cost benchmarking and review best practices with transportation industry experts. It can be an effective means of assembling collateral and aligning stakeholders in support of a larger and more impactful project, and Schneider can become a strategic partner to ensure success every step of the way.

Supply chain optimization key takeaways

- Supply chains are complicated and often full of operational complexity.

- The easiest way to transform a supply chain into a powerful strategic asset is to reduce inefficiencies and reconfigure logistics operations to align with long-term objectives.

- Network optimization, driven by data science, is the most effective way to generate impactful cost savings.

- Baseline analysis projects, like those done by the engineers at Schneider, can be a meaningful first step to get the ball in motion and identify a path and timeline to savings.

Get an expert supply chain assessment

Solve the operational complexity in your supply chain with an assessment from Schneider logistics experts.

Drive your business forward

Sign up to receive our industry leading newsletter with case studies and insights you can put to use for your business.