Shipper | Best practices

Loading guide for intermodal containers moving to California and Nevada

Understand the restrictions and challenges for shippers and consignees in California and Nevada due to California's bridge law.

Loading containers

- Containers are built much stronger than a standard trailer.

- A container needs to be built tough to handle the stresses placed on it during its service life.

- The average container and chassis combined weigh about 1,500 pounds more than a trailer.

- The additional weight combined with the California bridge law adds challenges for shippers and consignees in California.

Challenges and loading guidelines to adhere to the California bridge law

The commercial vehicle may not exceed 80,000 lbs. Gross Vehicle Weight (GVW), and the axle weight restrictions are:

- 34,000 lbs. on the drive tires

- 34,000 lbs. on the tandems

- 12,000 lbs. on the steer tires

When loading a container for California there are basic principles to remember:

- Load heavier pallets in the nose followed by light pallets to lightest pallet.

- Keep the product between the tandems and the nose of the container. The heavier the load the shorter you want it to be. For loads over 43,000 lbs., try to end the load between the 43-foot and 45-foot mark.

- Loads with a payload of 30,000+ lbs. must be scaled at origin per the California bridge law.

- Loads are scaled at origin based on the legal requirements of the destination state.

- For loads moving to California the tandems must be in the first hole for type A chassis and the fifth hole and forward for type B chassis.

California Department of Transportation truck restriction procedures

Combination vehicles coupled together, such as a truck tractor and semi-trailer or a truck tractor, semi-trailer and trailer, are limited to 65 feet, or 75 feet, or maybe unlimited depending on route. In addition, legal trucks in California must not exceed a kingpin-to-rear-axle (KPRA) length of 40 feet. Truck lengths and routes are discussed in detail in the Caltrans fact sheet Truck Route Classifications.

- The distance from the center of the kingpin to the center of the rear axle cannot exceed 40 feet.

- Schneider container tandems must be set in the correct hole according to the tandem guide for a type A or B chassis.

- Loads are scaled at origin to ensure they are legal for the destination state.

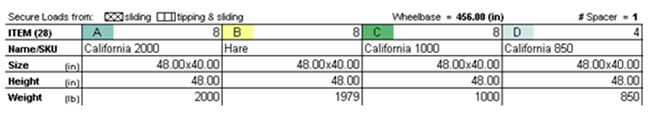

Example California bridge law load

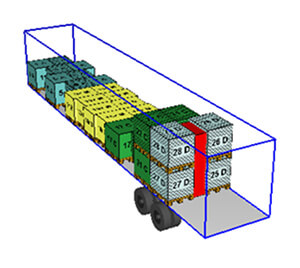

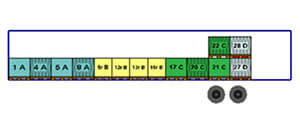

The colors denote the various weights and placement within the container. The heaviest product (blue)is loaded in the nose followed by the next lightest (yellow) and then (green) finalizing with the lightest.

The load is balanced, the drive axles weight 33,519 and the tandem axle weighs 33,595. The tandems are configured for California (1st hole).

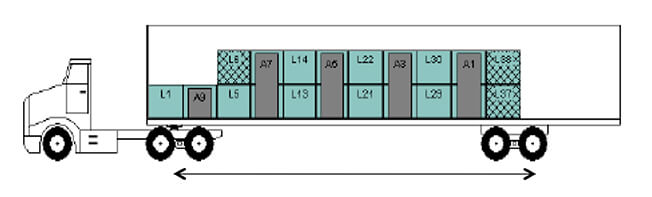

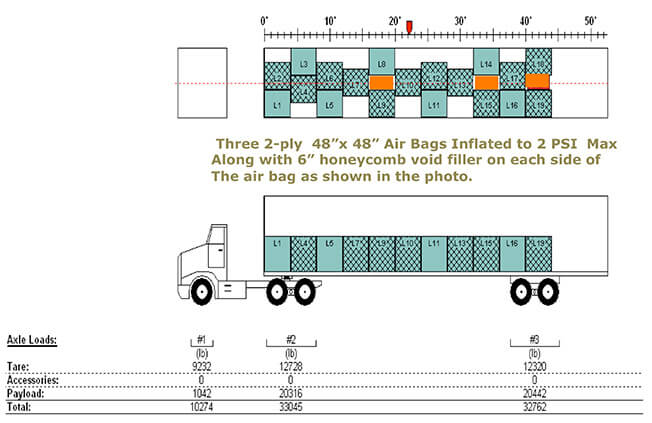

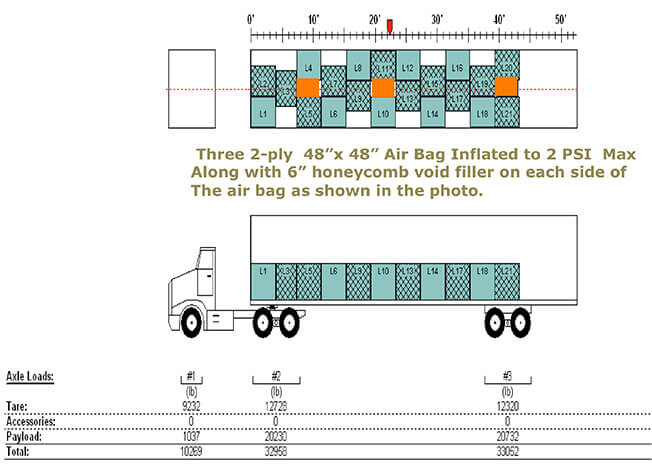

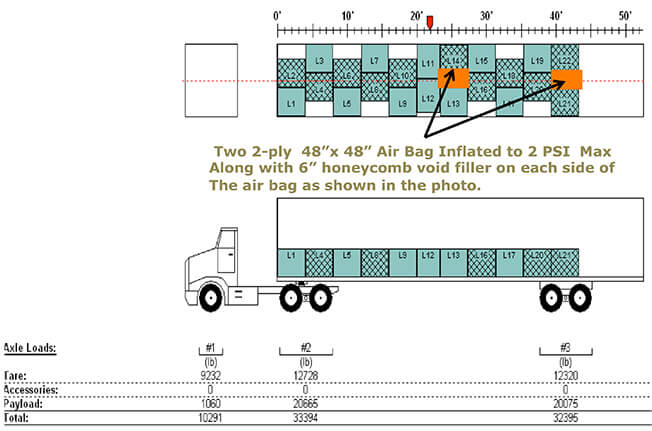

Load diagram for nineteen 48x40 pallets at 2,200 lbs. loaded straight

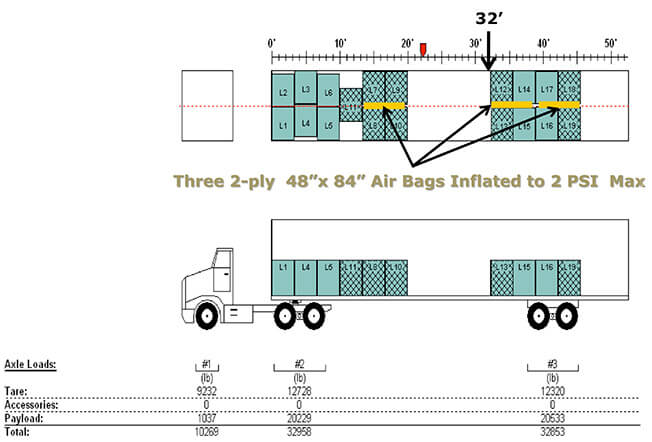

Load diagram for a split load of nineteen 48x40 pallets at 2,200 lbs.

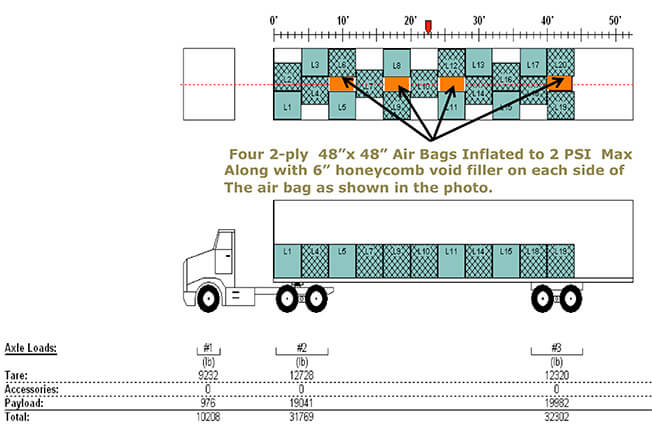

Load diagram for twenty 48x40 pallets at 2,000 lbs. loaded straight

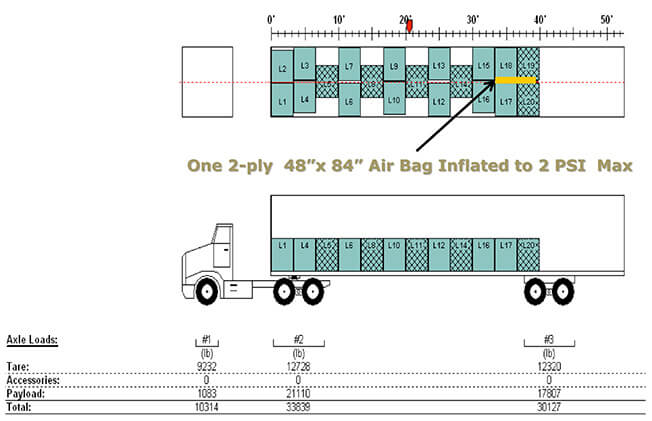

Load diagram for twenty 48x40 pallets at 2,000 lbs. loaded crossways

Load diagram for twenty-one 48x40 pallets at 2,000 lbs. loaded straight

Load diagram for twenty-two 48x40 pallets at 1,900 lbs. loaded straight

For customized loading diagrams or if you have questions about loading containers destined for California and Nevada in adherence with the California bridge law, Schneider’s Intermodal engineering experts are ready to help.

Contact Gary Jashinsky at 920-246-1253 or jashinskyg@schneider.com.

Drive your business forward

Sign up to receive our industry leading newsletter with case studies and insights you can put to use for your business.