Shipper | Case study

Custom staging for high-value product launches and promotions

Background: New product launches require high-security coordination across multiple retail outlets

A major player in the consumer electronics industry releases a new slate of personal devices at least once per year, distributed by big-box and warehouse retail outlets.

In addition to new product launches, the manufacturer runs special promotions a couple of times per year with the same retailers. The manufacturer ships fully-assembled in-store display units to each retailer’s distribution centers to support these efforts.

Situation: Product must arrive safely and quickly at a reasonable cost

To meet the strict deadlines of these promotions and product launches, the manufacturer arranged shipping from a display company assembling the in-store units directly to the individual distribution centers (DCs).

This process involved either less-secure Less-than-Truckload (LTL) shipments or full truckload rates, even when a load might only contain a few pallets.

The manufacturer needed a solution that was secure, fast and cost-effective – and with a carrier who could safely and securely move from initial inquiry to delivered freight in a week or less. The manufacturer would often run two or more of these special, time-sensitive projects simultaneously.

Schneider’s solution: custom staging to maximize trailer space combined with high-security practices and secure drop lots

Schneider’s Expedited team has the expertise and capacity to meet and exceed the manufacturer’s expectations.

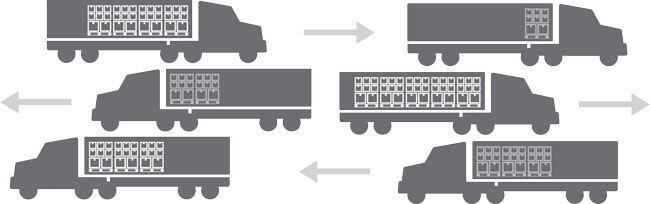

- Starting with a project bid, Schneider finds opportunities to combine multiple products into single shipments, and to use multi-stop loads to maximize capacity utilization, which saves time and money for the shipper.

- From there Schneider engineers the safest routes and continually communicates with team drivers to ensure every step of the security procedures are followed. Some of those procedures include team drivers arriving at the shipper’s location fully fueled and ready to run.

- Also, Schneider creates a staging plan for each load that ensures the right pallets are available at each stop to meet the parameters of the shipper and consignee pick up window.

- Schneider also stores full truckloads in its network of high-security yards, to allow for delayed delivery when needed. For each new product release, a customized plan is put together based on the manufacturer’s requirements.

Results: timely product launches, zero cargo theft, quick turnaround

Schneider’s customized security solution enables the manufacturer to roll out a coordinated, worry-free new product launch across multiple retail outlets. These projects are typically carried from conception to completion in two weeks. By combining loads for different consignees into single truckloads, Schneider saves the manufacturer from purchasing costlier freight with a single trailer for each distribution center, or purchasing less-secure less-than-truckload (LTL) freight.

As a result, Schneider has been the carrier of choice for the manufacturer’s secure freight needs for the past 6 years. This allows Schneider to continually evolve the process, and develop a deep level of integration between the manufacturer’s transportation professionals and Schneider drivers and customer support.

Interested in what Schneider can do for your high-value, time-sensitive freight needs?

Contact us at solutions@schneider.com.

Drive your business forward

Sign up to receive our industry leading newsletter with case studies and insights you can put to use for your business.