Shipper | Case study

Custom Dedicated trailers create safer UTV transportation

Transporting UTVs is a complex process, and if a provider isn’t careful, damage is accrued in transit and/or during delivery — a problem for both dealers and manufacturers.

Complex loads require innovative, safety-minded transportation provider

A global manufacturer of off-road vehicles was looking to diversify its base of transportation providers — but not just any provider would do for this type of complex haul. In order to mitigate in-transit damage to dealerships, only a safe, experienced provider would fit the bill. The manufacturer initially approached Schneider because of its known rigorous safety standards. Those early conversations opened the door to a shipping experience that — like the vehicle itself — pushed the boundaries far past what the manufacturer had hoped for in a dedicated transportation provider.

Evaluating current operations and understanding UTV transportation

The manufacturer and Schneider scheduled onsite assessments to review current operations and determine whether any enhancements to the UTV transportation process could be made. Schneider discovered that the current ramping being used was not specifically designed for the current unloading model, making it an extreme liability to the manufacturer’s brand. Additionally, Schneider visited UTV dealerships to familiarize themselves with the product, hear how it had been transported to date and uncover where improvements could be applied from the dealers’ point of view. For all of these visits, Schneider brought members from its engineering team to see the loading and unloading process and hear from the dealers firsthand. These onsite visits provided a wealth of information and acted as the catalyst for innovative and impactful change for transporting UTVs.

How engineering and training optimized UTV transportation

For the next three months, Schneider researched and conceptualized the best way to optimize UTV transportation and delivery methods, collaborating with the manufacturer along the way. At the end of the planning phase, Schneider proposed the following:

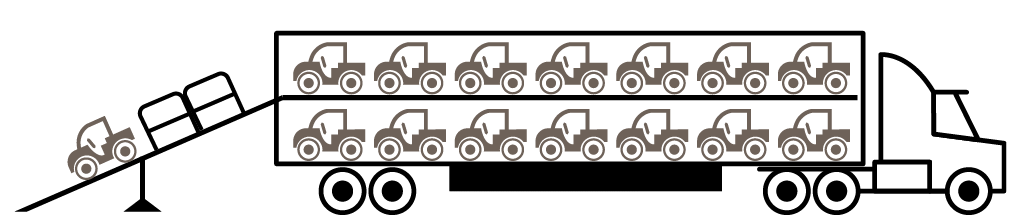

Custom trailers. An initial run of 25 double-decker trailers would be made specifically for hauling the manufacturer’s UTVs. These specially designed trailers would include customized ramping technology with guardrails that secured to the trailer for enhanced safety during the loading and unloading of vehicles on the second deck. A dovetail design was also incorporated onto the trailer for easier and safer vehicle unloading from the lower deck.

Account reference guides. For each dealership, detailed profiles would be created that contained pertinent delivery information for the driver. Information such as the preferred delivery windows, where to park and unload, and the appropriate contact at the dealership would be included so that the driver would feel confident when making deliveries. This component ensured drivers knew what to expect for their assigned dealership, and dealers knew what instructions the drivers were working with.

Driver training and certification. A three-day required training course would teach drivers:

- How to safely drive the UTVs on and off the ramps

- Proper setup of the ramp

- Nuances of the custom-made trailer

The manufacturer was impressed with Schneider’s diligence around safety practices and its engineering expertise, as well as the collaborative way in which the process unfolded. The dedicated UTV transportation solution not only enhanced previous delivery practices but was truly unique to the manufacturer. Because of the customized and innovative plan, UTV damage was reduced and delivery processes were streamlined.

Establishing ongoing process innovation

Since then, Schneider and the manufacturer have continued to ideate and evolve delivery processes and the equipment. Over 125 custom trailers have been produced, and the newest models are now equipped with an enhanced ramp setup and a reconfigured top deck that’s on an internal hydraulic lift. Additionally, Schneider has designed a three-tier trailer to accommodate the transportation of three-wheeled UTVs.

In the beginning, all the manufacturer was looking for was an additional dedicated transportation provider to help move its UTVs from point A to point B safely. What it got was far more valuable — robust analysis, engineering expertise and collaboration that yielded custom trailers and process improvements that truly put safety first. Additionally, relationships with dealers improved because of the keen attention to detail and clearly defined process. For riders looking for their next rig, the manufacturer can rest easy knowing their UTVs are delivered showroom-ready — and ready to make a big impact on the bottom line.

Drive your business forward

Sign up to receive our industry leading newsletter with case studies and insights you can put to use for your business.