Shipper | Case study

Network optimization delivers inventory and service level result

Background

A national beverage company was struggling to understand how to best expand its Multi-Region footprint. Mergers, along with continual organic growth, led to uneven shipment volumes which caused staffing and warehouse space abundance on some days and shortages on others. The company’s customer wholesalers were frustrated because of constant work to balance inbound loads against consumer needs, all while managing expiration dates. Seasonality was an area of focus that needed to be top of mind as nearly half of the company’s annual volume moves happen over a four-month period. All combined, this resulted in:

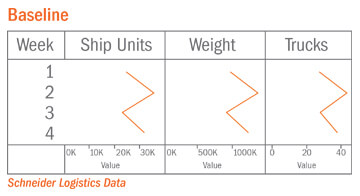

- Uneven shipment caused a 10% variation in volumes across weeks.

- Poor utilization as trucks were less than 75% full, more than half of the time.

- Peak months (4) accounted for 45% of annual volume.

- High costs and unpredictable service stemmed from lack of centralized information.

Solution

Schneider Logistics worked with the shipper to uncover root causes and identify key metrics that were crucial to drive success. Particularly, placing focus on the appropriate balance of service and cost. Schneider’s supply chain engineers were able to identify optimization opportunities which included:

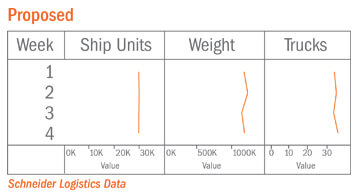

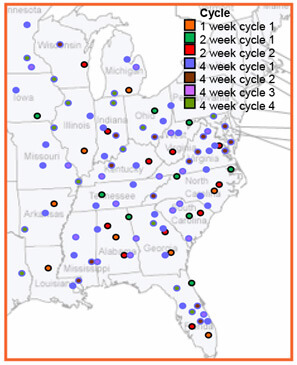

- Creating an outbound shipping strategy that balanced weekly volume and maximized consolidation opportunity

- Improved utilization on single stop freight by holding shipments until full truckloads were needed

- Increasing efficiencies with shipments and inventory levels by identifying warehouse specific patterns and determining optimal replenishment schedules to maximize cost savings

Weekly shipment volumes

Value

Schneider’s optimization model successfully dropped the customer’s transportation costs, while simultaneously freeing up its Operations, Customer Service, Sales and Finance employees to focus on top line growth.

- 7% reduction in total transportation cost

- 5% average increase in customer order spend

- 14% reduction in administrative follow up and customer support

- 11% reduction of miles per load

- 8% reduction in service claims

- Better week-over-week balance drove operating efficiencies

- Improved scheduling of wholesaler delivery dates and times has led to better relationships and higher sales

- Enabled growth by seamlessly accessing a national distribution network

Post-implementation, Schneider maintained close communication to monitor the ongoing success. Efficient execution and change management has ensured that total savings were above plan three and six months beyond implementation.

Schneider’s network engineering and optimization expertise has been proven time after time, in industry after industry. When you need smart solutions for complex challenges in your supply chain, contact Schneider.

Drive your business forward

Sign up to receive our industry leading newsletter with case studies and insights you can put to use for your business.