Shipper | Case study 6 min. read

Transportation optimization study reveals multi-million annual savings opportunity

Supply chain assessment and transportation optimization study reveal multi-million dollar savings opportunity for American HVAC manufacturer.

When you ask shippers what keeps them up at night, the issue around cargo security is likely a top contender. Just one stolen load of cargo in a year can wreak havoc on a business’s bottom line, let alone four. This was the reality for a technology manufacturer that develops and sells computers and related IT products.

Schneider’s engineering team used a representative sample of the customer’s historical shipment data to conduct the transportation optimization study. Best-in-class technology and modeling tools were put to work in a detailed analysis where the team replicated the customer’s processes and Transportation Management System (TMS) to test the impact of various business rules and their effect on transportation cost.

Scenarios tested

- Baseline.

- Mode selection.

- Daily consolidation.

- 2-day consolidation.

- Multi-stop truckload with daily consolidation.

- Multi-stop truckload with 2-day consolidation.

Manual transportation management has a high cost

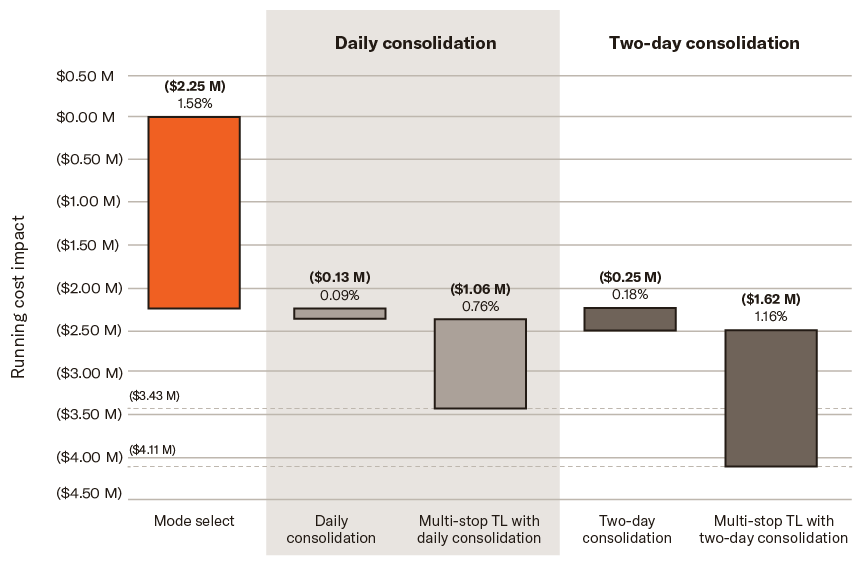

While the manufacturer utilizes a TMS, it manually plans its transportation in siloed business units and separates orders for warehouse ease, resulting in transportation inefficiencies. The transportation optimization study revealed that minor tweaks to the transportation strategy – simply choosing the most cost-effective mode – would drive significant cost savings of around $2.25 million annually. Further, it revealed that if the manufacturer were to move to a multi-stop truckload model in combination with 2-day consolidation the business could save over $4 million each year.

Beyond transportation costs, consolidation of the manufacturers freight from Less-than-truckload (LTL) into full or multi-stop truckload would reduce the annual number shipments by over 15%, reduce LTL related damage and claims, as well as improve on time delivery and customer service.

Implementing an optimized transportation strategy

By making logical choices for shipment mode this manufacturer will be able to save $2.25M annually. So, whether your business decides to get after low-hanging fruit or make larger operational changes, Schneider is here to ensure the path forward is smooth. Our operations teams work closely with customers to guide through the change management process from facility organization to creating shipment staging areas, and more.

Contact us

Legacy business rules may be costing your business more than you realize. Speak with a supply chain expert about optimizing your transportation strategy.

Drive your business forward

Sign up to receive our industry leading newsletter with case studies and insights you can put to use for your business.