Shipper | Case study 2.5 min. read

Intermodal heavyweight shipping saves 10% on annual transportation

Rapidly growing retailer gains cost savings and efficiency with lightweight equipment solution.

Rapid growth causes transportation breakdown

A leading specialty retailer in the hard surface flooring market was transporting products from its Savannah, Georgia distribution center to its stores in Illinois and New Jersey. The retailer’s rapid year-over-year growth of 20% began to create challenges in securing enough capacity to support current and future growth.

Changing business needs require the right mix of transportation services

The flooring retailer, which already had a strong, established presence in the Southeast, was expanding into the Northeast, Southwest and West Coast. This growth drastically increased the amount of product that needed to be distributed out of Savannah, stressing its supply chain.

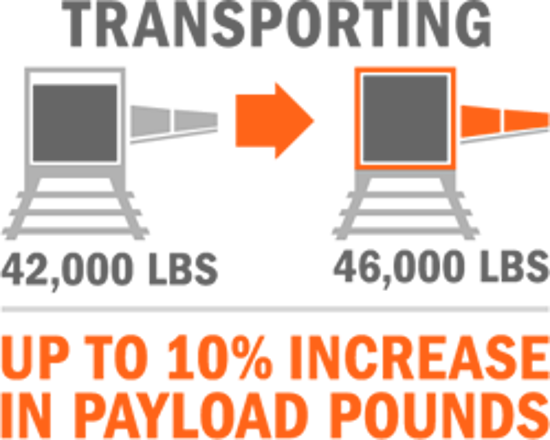

To fulfill demand, up to 100 truckloads of heavyweight product were being shipped from Georgia to Illinois and New Jersey weekly. Concerned with exceeding the maximum allowed weight by its current intermodal providers, the retailer was restricting its payload per container to 42,000 pounds. The retailer was unable to optimize its cost per pound, increasing the number of trucks needed to move its product — and resulting in higher overall landed costs.

Schneider engaged with the retailer and challenged it to think about its supply strategy differently. By shifting from a cost-per-linehaul model to a cost-per-ton model, which used a heavyweight intermodal solution, the retailer could gain capacity while reducing costs.

Lightweight equipment allows for a heavyweight intermodal solution

Schneider’s asset-based intermodal solution provided the shipper with reliability in equipment, capacity and service. The engineered solution included the use of Schneider’s company-owned day cabs, 53-feet long cube containers and lightweight chassis that allowed for a heavyweight solution achieved from consistency in equipment weight. Taking advantage of a heavyweight intermodal solution — transporting 46,000 pounds versus 42,000 pounds with the previous provider — was a game changer for the retailer.

This solution put more product on a truck, reducing the number of trucks needed. This is where the cost-per-linehaul versus cost-per-ton came into play: because Schneider used fewer trucks to transport product, the retailer saw a decrease in costs and increased efficiency.

POTENTIAL SAVINGS CALCULATOR |

|||

Payload Pounds |

42,000 |

46,000 |

10% |

Loads per week |

80 |

73 |

-9% |

Annual cost |

$8,320,000.00 |

$7,592,000.00 |

-9% |

Annual Minimum Savings |

$728,000.00 |

-9% |

|

Creative asset-based solution enables growth and reduces costs

After a successful pilot program, the retailer awarded Schneider the Chicago and New Jersey store deliveries. This solution delivered the following benefits to the retailer:

- Reduced supply chain costs by nearly 10% through higher payload

- Reduced truck moves by 10%

- Provided the retailer more capacity and more reliable service as it grows into more locations

By providing a proactive evaluation of needs and opportunities, Schneider delivered a solution that increased capacity and decreased costs. Moving forward, the retailer can continue to grow its business, knowing that product is moving consistently and efficiently from port to store.

Contact us

Now is the time to learn how you can also gain capacity while saving costs. Schneider Intermodal’s engineering experts will analyze your freight to uncover how much you can save by shipping on our company-owned heavyweight assets.

Drive your business forward

Sign up to receive our industry leading newsletter with case studies and insights you can put to use for your business.