Shipper | Case study

Schneider tackles port logistics problems for global importer of medical supplies

Port strategy improvements drive demand for supply chain network overhaul

Business growth leads to port logistics pains

Growth is good, but it often creates unforeseen consequences throughout the supply chain. A global medical supplies and equipment company recently learned that those consequences sometimes come with painful side effects. After the company steadily expanded its nationwide footprint through a series of acquisitions, it was left with a disjointed supply chain with efficiency gaps.

What started as minor annoyances increasingly became red flags in the company’s port logistics processes. The tipping point came when its dray operation out of Chicago experienced operational setbacks because of a road closure, and the incumbent transportation provider was permanently adjusting its rates because of the reroute.

After that hassle, coupled with less-than-stellar service, the medical supplies company knew it was ready to make a change. But what it didn’t yet know was even more significant: By addressing one piece of its supply chain, the company would set in motion a positive chain of events that would lead to a strategic, more comprehensive approach to its import supply chain.

Finding a transportation provider that checked all the strategical boxes

While looking for a fresh start in the Windy City, the medical supplies company sought a transportation provider that could truly make an impact on its port logistics problem. The nuances of importing freight into Chicago meant it needed a provider that could rise to the occasion. Must-haves included:

In addition, the company’s leadership team, with members in the United States as well as Ireland, knew it needed consensus on all changes to port logistics processes moving forward.

Research was completed, and Schneider landed on its short list of contenders. After several conversations between Schneider and the company’s key stakeholders, both domestic and abroad, the company awarded Schneider the Chicago dray lane. That meant Schneider was responsible for draying approximately 1,700 containers annually to the company’s regional distribution center located an hour outside of the city.

The medical supplies company was impressed when reductions in demurrage and detention fees were actualized within the first 60 days of operation. Plus, the company was given access to daily reporting that integrated with its electronic data interchange (EDI). A dedicated customer service group was also ready to answer questions, giving the company unprecedented, real-time visibility into the status of its freight. Right away, those differentiators confirmed that the company had made a meaningful move.

Exploring more ways to perfect port performance

Success in Chicago convinced the medical supplies company to take a fresh look at the port logistics strategy for its extensive supply chain network. The company had a vision of how it should operate, but it wasn’t sure how to make that happen. Once again, the company’s international team turned to Schneider for insight on how to move away from individual port fixes and toward a more holistic approach. The company shared key business details with Schneider, and the transportation provider delivered with customized recommendations.

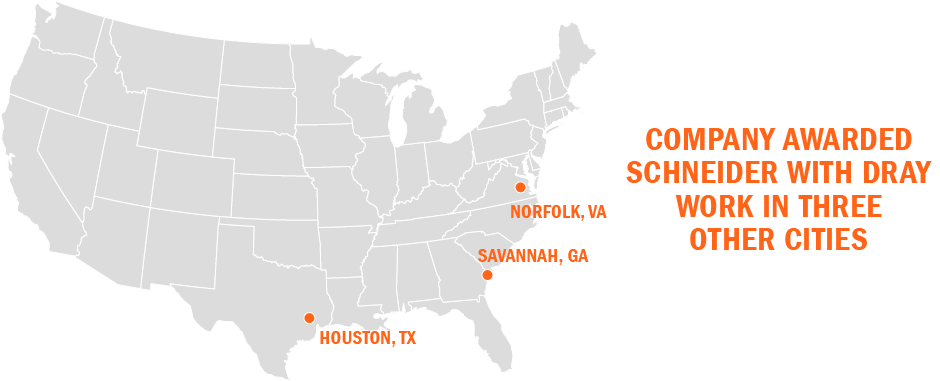

The medical supplies company was invigorated by the insightful ideas, and it committed to making even more network-wide enhancements. As a result, it awarded Schneider with dray work in three other cities: Savannah, Georgia; Houston, Texas; and Norfolk, Virginia.

As those ports showed positive progress, the medical supplies company awarded Schneider even more dray lanes. The company saw the value Schneider brought to the table, not just as a port drayage provider but as a strategic supply chain partner that could help meet its goals, overcome network issues and help make the supply chain more efficient. At this point, the company was ready to take the next step in revamping its port logistics strategy: transloading.

Spreading more strategy across the supply chain

Transloading wasn’t a new concept for the medical supplies company, but it wasn’t clear how transloading would integrate within and, ultimately, benefit its supply chain. Schneider conducted a supply chain analysis and presented the efficiencies of transferring cargo from the inbound ocean containers to another mode of transportation before transporting the products to customers. With clear insight into how transloading would be beneficial to its business, the company was ready to begin in Savannah. Schneider services five distribution centers in the Southeast, where it sorts, palletizes and enhances the receiving process before shipping the freight for final delivery.

With transloading well underway, the company was energized at the thought of even greater optimization. Now it expressed interest in tackling the importing and warehousing operations on the West Coast. Additional conversations with and analysis from Schneider led to a national redistribution strategy. This new approach would optimize freight coming into the Port of Los Angeles, using Schneider’s warehouse in Fontana, California for storage and distribution. The transportation provider would implement the same optimized systems being used in Savannah, which would enhance the company’s West Coast supply chain network.

A natural progression of port logistics optimization

A supply chain network overhaul doesn’t happen overnight. Enhancing a single dray lane fueled the medical supplies importer’s desire to strategically reimagine its import strategy to achieve a more unified and comprehensive port logistics strategy. The company wanted to feel empowered in the choices it was making, which required education, communication, visibility and results.

Schneider rose to the occasion on all fronts. Since beginning to work with the transportation provider, the medical supplies company has seen a sophisticated supply chain network take shape with the following benefits:

Reduced demurrage and detention fees

Reduced demurrage and detention fees

Improved delivery times

Improved delivery times

Improved accuracy on receiving

Improved accuracy on receiving

Reduced dwell time at the warehouse

Reduced dwell time at the warehouse

Enhanced utilization of the outbound trailers

Enhanced utilization of the outbound trailers

Knowledge is power, and one successful improvement at the ports created a ripple effect of strategic enhancements. By leveraging Schneider’s port logistics expertise, the medical supplies company not only got greater visibility into its freight but also gained insight into how to be a more strategic importer. The company loves its better bottom line, but greater empowerment at the ports is priceless.

Looking for a port logistics solution to enhance your supply chain? Contact

Drive your business forward

Sign up to receive our industry leading newsletter with case studies and insights you can put to use for your business.